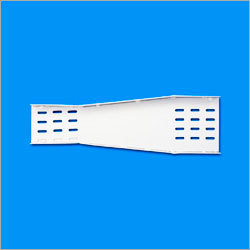

Vertical Bend Internal

Vertical Bend Internal Specification

- Max. Working Load

- 50 kg

- Conductor Material

- Steel

- Deflection

- Less than 1.25 mm

- Material

- GI (Galvanized Iron)

- Standard Thickness

- 1.6 mm

- Length

- 300 mm

- Width

- 100 mm

- Side Rail Height

- 50 mm

- Weight

- 2.1 kg

- Dimension (L*W*H)

- 300 mm x 100 mm x 50 mm

- Color

- Silver Grey

- Bend Angle

- 90 Degrees

- Environmental Compliance

- RoHS Compliant

- Corrosion Resistance

- Yes

- Installation Type

- Indoor/Outdoor

- Mounting Type

- Bolted

- Fire Resistance

- Up to 750°C

- Manufacturing Process

- Cold Rolled

About Vertical Bend Internal

Clients can avail from us a high quality range of Vertical Bend Internal. Our professionals manufacture this part making use of certified quality raw material with the help of state-of-the-art technology. Vertical Bend Internal is available in a variety of specifications as per the precise needs of clients. This product is highly appreciated for dimensional accuracy, optimum performance, corrosion resistance and longer service life. Clients can avail this product at highly competitive prices.

Optimized for Durability and Safety

Manufactured from galvanized iron with a cold-rolled process, this vertical bend offers superior corrosion and fire resistance, making it an excellent choice for high-demand settings. Its robust construction and ability to withstand temperatures up to 750C ensure safety and performance during critical events.

Versatile Usage for Indoor and Outdoor Applications

Whether you are organising cable pathways in industrial facilities or commercial complexes, this products adaptability allows seamless installation in both indoor and outdoor environments. The standard dimensions and mounting design make it easy to integrate into existing systems.

Efficient and Compliant Engineering

Exhibiting RoHS compliance and built to sustain environmental challenges, this vertical bend prioritizes both safety and sustainability. Its steel conductor material and bolted mounting guarantee strength while supporting eco-friendly construction standards.

FAQs of Vertical Bend Internal:

Q: How is the Vertical Bend Internal installed in cable management systems?

A: The product is designed for bolted mounting, allowing secure attachment to trays or support structures. Thanks to its standardized dimensions (300 mm x 100 mm x 50 mm), installation is straightforward for both new and existing cable systems.Q: What makes this vertical bend suitable for indoor and outdoor use?

A: The galvanized iron construction provides excellent corrosion resistance, while the silver-grey finish ensures durability against environmental factors. Its robust manufacturing process makes it ideal for both indoor facilities and outdoor applications.Q: When should I use a 90-degree vertical bend in my setup?

A: A 90-degree vertical bend is essential when cables need to change direction between vertical planes, such as ascending through floors or routing cables upward or downward between levels, ensuring minimal cable stress and efficient routing.Q: Where can this vertical bend be applied most effectively?

A: This product is suitable for industrial plants, commercial buildings, or data centers where reliable, fire-resistant cable routing is necessary. Its fire resistance of up to 750C and RoHS compliance make it ideal for safety-critical environments.Q: What is the manufacturing process for this vertical bend and how does it benefit performance?

A: Produced through a cold-rolled process, the bend features uniform thickness (1.6 mm) and enhanced structural integrity. This manufacturing method offers added durability, greater load-bearing capacity (up to 50 kg), and low deflection.Q: How does being RoHS compliant benefit the user and the environment?

A: RoHS compliance ensures the product is free from restricted hazardous substances, making it safer for users to handle and environmentally friendly during its lifecycle, supporting green building standards.Q: What advantages does the fire resistance up to 750C provide?

A: Withstanding temperatures of up to 750C, this vertical bend offers critical protection for cables in high-heat scenarios, helping maintain operational integrity and safety during fire emergencies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Trays & Accessories Category

Center Reducer

Product Type : Other , Center Reducer

Color : Other, Galvanized Silver

Standard Thickness : 1.6 mm

Length : 200 mm

Material : Other, Mild Steel

Side Rail Height : 50 mm

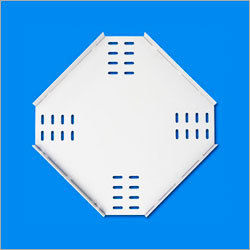

Horizontal Cross

Product Type : Other , Horizontal Cross

Color : Other, Silver / Metallic Grey

Standard Thickness : 1.2 mm to 2.5 mm

Length : 150 mm to 1200 mm

Material : Other, Mild Steel / Stainless Steel / Aluminium / GI

Side Rail Height : 25 mm to 150 mm

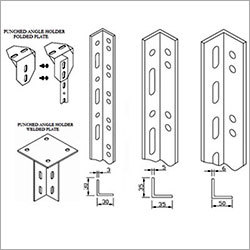

Punched Angle Support System

Product Type : Other , Punched Angle Support System

Color : Other, Silver, Customized

Standard Thickness : 1.5 mm, 1.6 mm, 2.0 mm, 2.5 mm, 3 mm

Length : 2 m, 2.5 m, 3 m

Side Rail Height : 35 mm to 75 mm

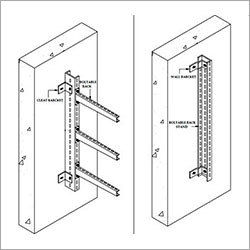

Cable Ladder Tray

Product Type : Other , Ladder Type Cable Tray

Color : Other, Silver, Galvanized, Painted as per requirement

Standard Thickness : 1.6 mm, 2.0 mm, 2.5 mm, 3.0 mm

Length : 2500 mm (standard), customizable as per requirement

Material : Other, Mild Steel (MS), Aluminum, Stainless Steel (SS)

Side Rail Height : 50 mm to 150 mm

GST : 27AABCP6228M1Z3

|

|

PROFAB ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry