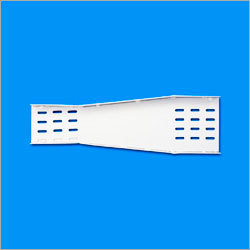

Center Reducer

Center Reducer Specification

- Surface Finish

- Hot Dip Galvanized

- Deflection

- Minimal (<2 mm at maximum load)

- Max. Working Load

- 45 kg

- Conductor Material

- Steel

- Product Type

- Center Reducer

- Material

- Mild Steel

- Standard Thickness

- 1.6 mm

- Length

- 200 mm

- Width

- 100 mm

- Side Rail Height

- 50 mm

- Weight

- 2.5 kg

- Dimension (L*W*H)

- 200 mm x 100 mm x 50 mm

- Color

- Galvanized Silver

- Connection Type

- Bolt Connection

- Corrosion Resistance

- Yes

- Compatible Tray Widths

- 100 mm to 200 mm

- Manufacturing Process

- Formed and Welded

- Reducer Type

- Cable Tray Center Reducer

About Center Reducer

Leveraging upon our vast industry experience, we are offering a quality-assured range of Center Reducer. It is manufactured in compliance with international standards using well-tested raw material. The offered range is highly appreciated for accurate dimensions, low maintenance, sturdy construction, corrosion resistance and durability. This Center Reducer is available in different technical specifications and can be customized on the specific demands of the clients. In order to ensure quality, this reducer is stringently tested on various parameters.

Efficient Cable Management for Varying Tray Widths

This Center Reducer provides a seamless transition between cable trays of different widths, allowing for organized and secure cable routing. Its formed and welded mild steel construction ensures strength, while hot dip galvanization offers robust corrosion protection. The bolt connection feature makes installation quick and reliable, suitable for both new and retrofit electrical cable tray systems.

Reliable Construction and High Load Capacity

Manufactured from standard 1.6 mm thick mild steel with a hot dip galvanized finish, this reducer guarantees longevity in demanding environments. It can handle up to 45 kg of cable load with minimal deflection, making it dependable for heavy-duty electrical setups. The galvanized silver color provides a professional look, complementing modern industrial spaces.

FAQs of Center Reducer:

Q: How is the Cable Tray Center Reducer installed?

A: The center reducer features a bolt connection system, making installation straightforward. Simply align the reducer with the cable trays of different widths and secure it using bolts at the provided connection points.Q: What are the benefits of using a hot dip galvanized finish?

A: The hot dip galvanized finish provides exceptional corrosion resistance, ensuring a long service life even in challenging or humid industrial environments. It also protects the underlying mild steel from rust and mechanical wear.Q: When should I use a center reducer in my cable tray system?

A: A center reducer is used when you need to transition between cable trays of different widths, typically to accommodate larger or smaller cable loads as they branch through your infrastructure. It maintains cable organization and system integrity during the width transition.Q: Where can this cable tray center reducer be employed?

A: This product is suitable for use in industrial settings, commercial facilities, and large-scale infrastructure projects where robust cable management is required and environmental resistance is important.Q: What is the manufacturing process of this center reducer?

A: The center reducer is manufactured using forming and welding techniques, which ensure precise dimensions, high structural integrity, and a smooth fit with standard cable trays.Q: How does the minimal deflection benefit my cable tray installation?

A: With a maximum deflection of less than 2 mm at full load, the reducer maintains the structural stability of your cable tray system, preventing cable sagging and reducing long-term maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Trays & Accessories Category

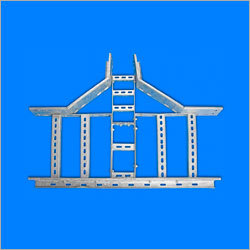

Cable Binder Tray

Product Type : Other , Cable Binder Tray

Color : Other, Silver

Side Rail Height : 50 mm

Deflection : < 2 mm at max load

Standard Thickness : 1.6 mm

Length : 2500 mm

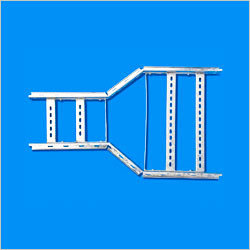

Cable Tee

Product Type : Other , Cable Tee

Color : Other, Silver

Side Rail Height : 50 mm

Deflection : Minimal

Standard Thickness : 1.6 mm

Length : 150 mm

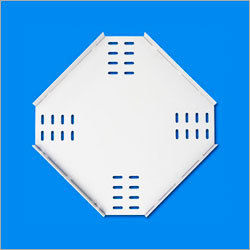

Horizontal Cross

Product Type : Other , Horizontal Cross

Color : Other, Silver / Metallic Grey

Side Rail Height : 25 mm to 150 mm

Deflection : Within permissible limits as per IS/IEC standards

Standard Thickness : 1.2 mm to 2.5 mm

Length : 150 mm to 1200 mm

Center Reducer For Connecting Bigger Cable Trays

Product Type : Other , Cable Tray Center Reducer

Color : Other, Silver/Grey

Side Rail Height : 50 mm / 75 mm / 100 mm

Deflection : Less than 2 mm under max load

Standard Thickness : 1.2 mm / 1.6 mm / 2.0 mm

Length : 600 mm to 1200 mm

GST : 27AABCP6228M1Z3

|

|

PROFAB ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry