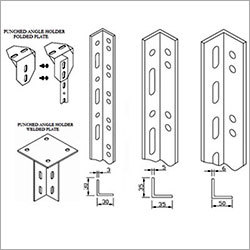

Punched Angle Support System

Punched Angle Support System Specification

- Conductor Material

- Steel

- Max. Working Load

- Up to 150 kg/m depending on size & thickness

- Deflection

- Within permissible IS standard limits

- Product Type

- Punched Angle Support System

- Standard Thickness

- 1.5 mm, 1.6 mm, 2.0 mm, 2.5 mm, 3 mm

- Length

- 2 m, 2.5 m, 3 m

- Width

- 35 mm, 40 mm, 50 mm, 60 mm, 75 mm

- Side Rail Height

- 35 mm to 75 mm

- Weight

- Approx. 1.53.2 kg/m (varies by size)

- Dimension (L*W*H)

- As per requirement (standard e.g. 2500 x 40 x 40 mm)

- Color

- Silver, Customized

- Compliance

- IS 2062 / IS 1079 Standards

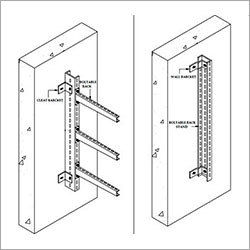

- Installation Type

- Bolted Assembly

- Corrosion Resistance

- Yes, due to galvanization

- Hole Size

- Typically 8.5 x 18 mm

- Usage/Application

- Cable/Tray Support, Shelving, Framing, Racking

- Accessories

- Nuts, Bolts, Brackets, Channel Joiners

About Punched Angle Support System

With the assistance of our dexterous team, we are offering a wide range of Punched Angle Support System that is available in different lengths up to 2500mm. It is made from high grade raw materials and cutting edge technology in compliance with international standards. This can be attached to floor, ceiling, wall or top of the racks as per the needs of the clients. The entire gamut of Punched Angle Support System is broadly appreciated for accurate dimensions, corrosion resistance, perfect finish and enhanced life.

Reliable Structural Support for Diverse Applications

Built to provide sturdy support across cable management, shelving, framing, and racking, this Punched Angle Support System caters to industrial and commercial needs. Its high-quality steel, galvanized for corrosion resistance, ensures durability in challenging environments. Suitable for heavy-duty applications, it conforms to industry standards for safety and performance.

Easy Installation and Customization

Installation is straightforward thanks to its bolted assembly system. Standard accessories like nuts, bolts, brackets, and channel joiners come included, allowing quick and secure setup. With customizable lengths, widths, and side rail heights, it adapts to a wide range of structural requirements, delivering flexibility for unique project demands.

Tested Strength and Superior Load Capacity

Designed to handle impressive loads up to 150 kg/m, this systems performance is validated against IS standard permissible deflection limits. Standard thickness up to 3 mm and meticulous quality control provide reliable structural strength, making it a trusted choice for weight-bearing applications in warehouses, factories, and more.

FAQs of Punched Angle Support System:

Q: How is the Punched Angle Support System installed?

A: Installation is performed using a bolted assembly method. Components are connected using provided nuts, bolts, brackets, and channel joiners, which enables a straightforward and secure setup without the need for welding or specialized tools.Q: What are the primary uses of the Punched Angle Support System?

A: This support system is typically used for cable and tray supports, shelving, framing, and racking in industrial and commercial settings, making it ideal for organizing electrical cables, storing goods, or building modular structures.Q: When should I choose galvanized steel for support systems?

A: Galvanized steel is recommended when you need long-lasting corrosion resistance, especially in environments prone to moisture or chemicals. The galvanization process protects the support system from rust, prolonging its service life.Q: Where can the Punched Angle Support System be installed?

A: These systems are suitable for use in warehouses, factories, electrical rooms, commercial storage facilities, and workshopsessentially any location that requires sturdy, customizable support structures.Q: What standards does the system comply with?

A: It is manufactured in accordance with IS 2062 and IS 1079 standards, ensuring it meets stringent requirements for quality, performance, and safety.Q: How does the customization process work for different project needs?

A: You can select length, width, side rail height, and thickness from available options or request specific dimensions. Manufacturers can tailor the support system to suit unique structural or load-bearing requirements.Q: What are the benefits of using this Punched Angle Support System?

A: The key benefits include high load capacity, resistance to corrosion, compliance with recognized standards, easy bolted installation, versatile application, and custom configuration optionsmaking it a reliable and cost-effective solution for many structural support needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Trays & Accessories Category

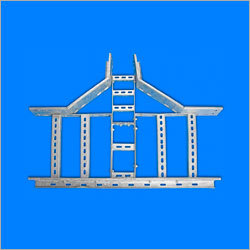

Cable Tee

Width : 150 mm

Standard Thickness : 1.6 mm

Color : Other, Silver

Side Rail Height : 50 mm

Deflection : Minimal

Length : 150 mm

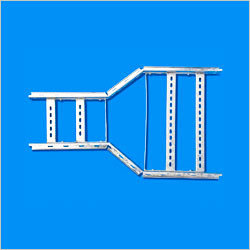

Horizontal Bend 45 Degree

Width : 100 mm

Standard Thickness : 2.0 mm

Color : Other, Silver / Grey

Side Rail Height : 50 mm

Deflection : <2 mm at full load

Length : 500 mm

Cable Ladder Tray

Width : 150 mm to 1200 mm

Standard Thickness : 1.6 mm, 2.0 mm, 2.5 mm, 3.0 mm

Color : Other, Silver, Galvanized, Painted as per requirement

Side Rail Height : 50 mm to 150 mm

Deflection : Limited to under 10 mm at max load

Length : 2500 mm (standard), customizable as per requirement

Center Reducer For Connecting Bigger Cable Trays

Width : 100 mm to 1000 mm

Standard Thickness : 1.2 mm / 1.6 mm / 2.0 mm

Color : Other, Silver/Grey

Side Rail Height : 50 mm / 75 mm / 100 mm

Deflection : Less than 2 mm under max load

Length : 600 mm to 1200 mm

GST : 27AABCP6228M1Z3

|

|

PROFAB ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry