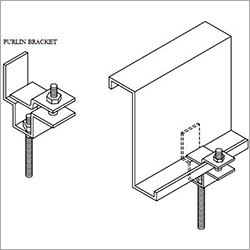

C Purlin Bracket

C Purlin Bracket Specification

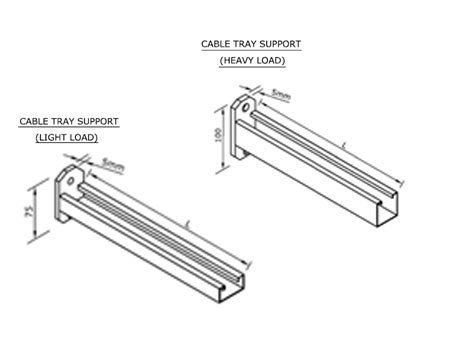

- Operating Pressure

- Ambient

- Accessories Type

- Mounting and fitting brackets

- Machine Type

- Fabrication and punching machine made

- Features

- Corrosion resistant, Easy installation, Durable construction

- Technology

- Cold Rolled Formed

- Surface Treatment

- Galvanized

- Type

- C Purlin Bracket

- Material

- Mild Steel

- Function

- Structural Support for Roofing and Wall Systems

- Color

- Silver (metallic finish)

- Hole Configuration

- Punched holes for easy bolting

- Thickness Range

- 1.5 mm 3.0 mm

- Length

- As per requirement or standard sizes

- Packaging Type

- Bundles or custom packaging

- Finish

- Zinc coated for added durability

- Load Bearing Capacity

- As per design/requirement

About C Purlin Bracket

Owing to our expertise in this field, we are the leading manufacturer and supplier of a high quality range of C Purlin Bracket. Designed and fabricated under the guidance of skilled professionals using high grade raw material, this product ensures a longer service life. This product is offered in different specifications to meet the varied needs of clients. The entire range is acknowledged for accurate dimensions, perfect finish, corrosion resistance, easy installation and longer life.

Features:

| 1. | Profab Innovation. |

| 2. | Eliminates need for Welding Supports on Z Purlin. |

| Table-1 | ||||||||||||||||||||

| ||||||||||||||||||||

Engineered for Versatile Structural Support

Our C Purlin Brackets serve as essential components in modern roofing and wall systems, enhancing stability and construction speed. Their mild steel construction and galvanization provide exceptional resilience, ensuring they perform reliably in diverse environments. Manufactured to precise design requirements and available in custom lengths, these brackets support a wide range of building projects, from warehouses to residential complexes, catering to varied load-bearing needs.

Exceptional Durability and Corrosion Resistance

Crafted using cold-rolled forming and finished with a zinc galvanization process, the C Purlin Bracket is built to withstand harsh climatic conditions. The metallic silver finish not only protects the bracket from corrosion but also ensures a professional appearance for visible installations. This treatment extends the products service life, making it a cost-effective solution for long-term use.

FAQs of C Purlin Bracket:

Q: How are C Purlin Brackets installed in construction projects?

A: C Purlin Brackets are designed with pre-punched holes for easy bolting, allowing for straightforward attachment to structural frameworks. Simply align the bracket according to your design specifications and secure it using bolts, making installation efficient and hassle-free.Q: What is the process behind manufacturing these C Purlin Brackets?

A: The C Purlin Brackets are manufactured from mild steel through a cold rolling process, followed by punching holes for bolting and surface treatment via galvanization. This process results in precise dimensions, enhanced durability, and strong corrosion resistance.Q: When should I consider using a C Purlin Bracket for my project?

A: C Purlin Brackets are recommended whenever you need structural support for roofing and wall systems, particularly in industrial, commercial, or residential buildings. They are suitable for both new constructions and retrofitting existing structures.Q: Where are these C Purlin Brackets typically applied?

A: These brackets are widely utilized in supporting roofing frameworks and wall panels in various settings such as warehouses, factories, commercial buildings, and homes. Their adaptability makes them suitable for an array of structural applications.Q: What are the benefits of the zinc-coated galvanized finish?

A: The zinc coating provides excellent corrosion resistance, ensuring the brackets withstand prolonged exposure to humidity and environmental stress. The galvanized finish also adds a sleek metallic appearance and extends the lifespan of the bracket.Q: Can the C Purlin Brackets length and hole configuration be customized?

A: Yes, both the length and hole configuration of the C Purlin Bracket can be tailored to meet specific project requirements. Standard sizes are available, but custom dimensions and punching patterns ensure perfect compatibility with varying design needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Support Systems Category

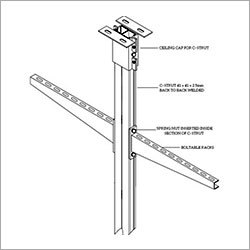

C Strut Racks

Minimum Order Quantity : 10 Pieces

Material : Metal

Size : Standard

Usage : Industrial

Surface Treatment : Polished

Color : Silver

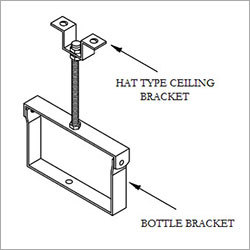

Bottle Bracket System

Minimum Order Quantity : 10 Pieces

Material : Metal

Size : Standard

Usage : Industrial

Surface Treatment : Polished

Color : Silver

Ceiling Application

Minimum Order Quantity : 10 Pieces

Material : Metal

Size : Standard

Usage : Industrial

Surface Treatment : Polished

Color : Silver

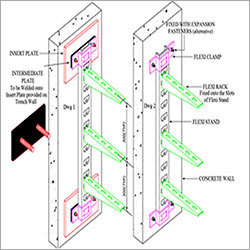

Flexi Rack Support System

Minimum Order Quantity : 10 Pieces

Material : Metal

Size : Standard

Usage : Industrial

Surface Treatment : Polished

Color : Multicolor

GST : 27AABCP6228M1Z3

|

|

PROFAB ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry